- 033-6902-9692 & 9093085089

- info@gnim.org

.png)

ENGINEERING

GENERAL MACHINIST

General Machinist Course at Gurukul National Institute and Management (GNIM)

Course Overview:

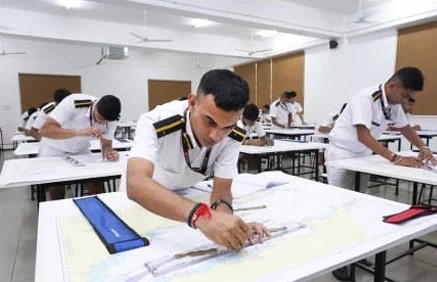

The General Machinist course at Gurukul National Institute and Management (GNIM) is a comprehensive program designed to equip students with the essential skills required for operating and maintaining various machinery in the manufacturing industry. This course provides both theoretical knowledge and practical training to prepare students for a successful career in metalworking and machining.

Students will learn to operate conventional machines like lathes, milling machines, and grinders, and also gain exposure to advanced machinery such as CNC (Computer Numerical Control) machines. By the end of the course, participants will be proficient in reading blueprints, using precision tools, and applying industry-standard techniques to achieve high-quality, precise mechanical parts.

Course Duration:

- 6 months to 2 years (depending on the program structure)

Mode of Study:

- Full-Time/Part-Time

Key Learning Outcomes:

- Gain hands-on experience in operating different types of machinery, including CNC machines, lathes, milling machines, and grinders.

- Learn to read and interpret technical drawings and blueprints.

- Master basic and advanced machining processes such as turning, milling, grinding, and drilling.

- Understand the importance of safety protocols and best practices in the workshop.

- Learn to maintain and troubleshoot various types of machinery.

- Develop proficiency in using measuring instruments to ensure accuracy in machining.

Course Content:

- Introduction to Machining:

- Basic concepts of machining and the role of machinists in manufacturing.

- Overview of tools, equipment, and materials used in the machining industry.

- Lathe Machine Operations:

- Fundamentals of turning, threading, and boring.

- Techniques for producing precise cylindrical parts.

- Milling Machine Operations:

- Overview of milling machines and their components.

- Techniques for creating complex shapes and surfaces using milling machines.

- Grinding Techniques:

- Surface grinding and cylindrical grinding.

- Achieving precise finishes on metal components.

- CNC Machining:

- Introduction to CNC programming and operations.

- Hands-on experience with CNC machine tools.

- Blueprint Reading and Technical Drawing:

- Understanding technical drawings and symbols.

- Using blueprints to guide machining operations.

- Workshop Safety and Maintenance:

- Safety protocols in the machining environment.

- Regular maintenance of machines to ensure optimal performance.

- Quality Control and Measurement:

- Using precision measuring tools such as micrometers, calipers, and height gauges.

- Ensuring high-quality standards in the production process.

Eligibility Criteria:

- Minimum educational qualification: [10th Grade or equivalent]

- Basic knowledge of mathematics and an interest in mechanical engineering is recommended.

Why Choose GNIM?

- State-of-the-Art Facilities: GNIM provides access to modern machinery and tools to ensure students receive hands-on experience with current industry standards.

- Experienced Faculty: Learn from highly skilled and experienced instructors with practical industry knowledge.

- Placement Assistance: GNIM offers placement support to help graduates secure rewarding careers in manufacturing and machining.

- Industry-Relevant Curriculum: The course is designed in collaboration with industry experts to ensure that students are job-ready upon graduation.

- Certification: Upon successful completion, students will receive a certificate that is recognized by industry leaders.

Career Opportunities:

- CNC Operator/Programmer

- Machinist

- Production Technician

- Machine Maintenance Technician

- Quality Control Inspector

- Tool and Die Maker

Enroll Today:

Start your journey toward a successful career in the machining industry with the General Machinist course at Gurukul National Institute and Management (GNIM). Gain valuable skills that will open doors to a variety of job opportunities in sectors like automotive, aerospace, and heavy machinery manufacturing.

.png)

.png)

.png)

.jpg)

.jpg)